Waist drum mixer

- Production capacity: 100-300 kg/p

- Applicable materials: Tea, grain, starch, vegetable fiber, milk powder, cocoa powder, flour, coffee, glucose

- Applications: Food, medicine, pesticides, zinc oxide, detergents, veterinary drugs, compound fertilizers, feed, petroleum, mining, building materials industry, coatings, dyes, pigments, auxiliaries, calcium carbonate, biological agents, ceramics, chemicals, flavors and

Classification:

Tel:

Introduction

-

The screw feeding crushing and mixing machine is mainly suitable for small feed factories and farms. It is suitable for crushing granular materials such as corn and soybean meal. Then mix. The machine adopts the technology of mixing while pulverizing. The pulverizer adopts a screw conveyor to transport the raw materials to be pulverized to the pulverizer. The rotor of the pulverizer can generate positive pressure in the cavity. Very efficient. The pulverized material enters the bottom of the mixing cylinder through the small dial at the bottom of the mixer, and then passes through the mixing shaft for mixing.

Mix together.

-

1. The machine adopts the dust isolation treatment of mechanical seal, which has a reliable sealing effect, the powder will not leak, and will not be damaged due to the rapid wear of the bearing due to the material entering the bearing;

2. The equipment adopts a quick-opening rotary valve, and the discharge port adopts a large-diameter 90° rotary valve, which is easy to use;

3. It can also be used for the mixing of liquid materials;

4. Customized spray or additive device according to customer requirements;

5. It can also be changed to a vacuum dryer.

-

Waist drum mixer is a new type of fine container rotary and stirring mixing equipment. It is used for uniform mixing of various powdery, granular and agglomerated materials. The machine adopts mechanical seal, the powder does not mix and leak, and the bearing has a long service life. The machine has high mixing efficiency, high work efficiency, low labor intensity and convenient operation. The machine is composed of double cones, mechanical seals, frame, deceleration drive, stirring blades, etc. The powder or granular material is added into the double-cone container. With the continuous rotation of the container, the material undergoes complex impact in the container, and the stirring blade rotates at a high speed to achieve uniform mixing.

-

Finished pellets

undefined

Features

-

- Commodity name: Waist drum mixer

- Production capacity: 100-300 kg/p

- Applicable materials: Tea, grain, starch, vegetable fiber, milk powder, cocoa powder, flour, coffee, glucose

- Applications: Food, medicine, pesticides, zinc oxide, detergents, veterinary drugs, compound fertilizers, feed, petroleum, mining, building materials industry, coatings, dyes, pigments, auxiliaries, calcium carbonate, biological agents, ceramics, chemicals, flavors and

The screw feeding crushing and mixing machine is mainly suitable for small feed factories and farms. It is suitable for crushing granular materials such as corn and soybean meal. Then mix. The machine adopts the technology of mixing while pulverizing. The pulverizer adopts a screw conveyor to transport the raw materials to be pulverized to the pulverizer. The rotor of the pulverizer can generate positive pressure in the cavity. Very efficient. The pulverized material enters the bottom of the mixing cylinder through the small dial at the bottom of the mixer, and then passes through the mixing shaft for mixing.

Mix together.

-

1. The machine adopts the dust isolation treatment of mechanical seal, which has a reliable sealing effect, the powder will not leak, and will not be damaged due to the rapid wear of the bearing due to the material entering the bearing;

2. The equipment adopts a quick-opening rotary valve, and the discharge port adopts a large-diameter 90° rotary valve, which is easy to use;

3. It can also be used for the mixing of liquid materials;

4. Customized spray or additive device according to customer requirements;

5. It can also be changed to a vacuum dryer.

-

Waist drum mixer is a new type of fine container rotary and stirring mixing equipment. It is used for uniform mixing of various powdery, granular and agglomerated materials. The machine adopts mechanical seal, the powder does not mix and leak, and the bearing has a long service life. The machine has high mixing efficiency, high work efficiency, low labor intensity and convenient operation. The machine is composed of double cones, mechanical seals, frame, deceleration drive, stirring blades, etc. The powder or granular material is added into the double-cone container. With the continuous rotation of the container, the material undergoes complex impact in the container, and the stirring blade rotates at a high speed to achieve uniform mixing.

-

Working Principle

-

- Commodity name: Waist drum mixer

- Production capacity: 100-300 kg/p

- Applicable materials: Tea, grain, starch, vegetable fiber, milk powder, cocoa powder, flour, coffee, glucose

- Applications: Food, medicine, pesticides, zinc oxide, detergents, veterinary drugs, compound fertilizers, feed, petroleum, mining, building materials industry, coatings, dyes, pigments, auxiliaries, calcium carbonate, biological agents, ceramics, chemicals, flavors and

The screw feeding crushing and mixing machine is mainly suitable for small feed factories and farms. It is suitable for crushing granular materials such as corn and soybean meal. Then mix. The machine adopts the technology of mixing while pulverizing. The pulverizer adopts a screw conveyor to transport the raw materials to be pulverized to the pulverizer. The rotor of the pulverizer can generate positive pressure in the cavity. Very efficient. The pulverized material enters the bottom of the mixing cylinder through the small dial at the bottom of the mixer, and then passes through the mixing shaft for mixing.

Mix together.

-

1. The machine adopts the dust isolation treatment of mechanical seal, which has a reliable sealing effect, the powder will not leak, and will not be damaged due to the rapid wear of the bearing due to the material entering the bearing;

2. The equipment adopts a quick-opening rotary valve, and the discharge port adopts a large-diameter 90° rotary valve, which is easy to use;

3. It can also be used for the mixing of liquid materials;

4. Customized spray or additive device according to customer requirements;

5. It can also be changed to a vacuum dryer.

-

Waist drum mixer is a new type of fine container rotary and stirring mixing equipment. It is used for uniform mixing of various powdery, granular and agglomerated materials. The machine adopts mechanical seal, the powder does not mix and leak, and the bearing has a long service life. The machine has high mixing efficiency, high work efficiency, low labor intensity and convenient operation. The machine is composed of double cones, mechanical seals, frame, deceleration drive, stirring blades, etc. The powder or granular material is added into the double-cone container. With the continuous rotation of the container, the material undergoes complex impact in the container, and the stirring blade rotates at a high speed to achieve uniform mixing.

-

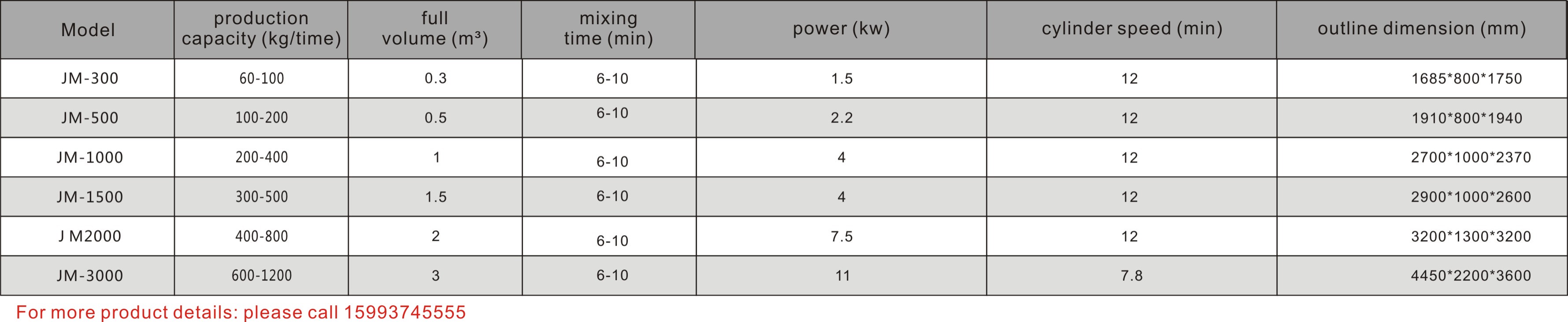

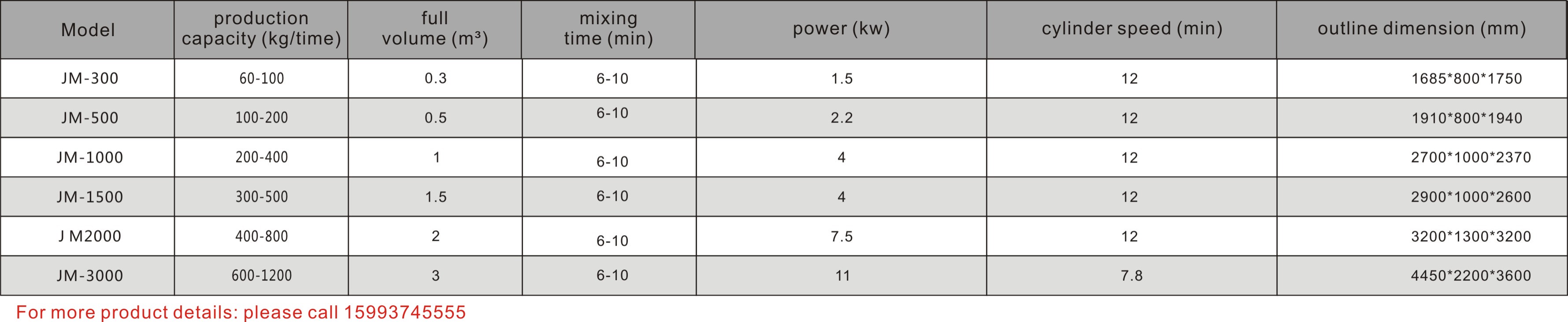

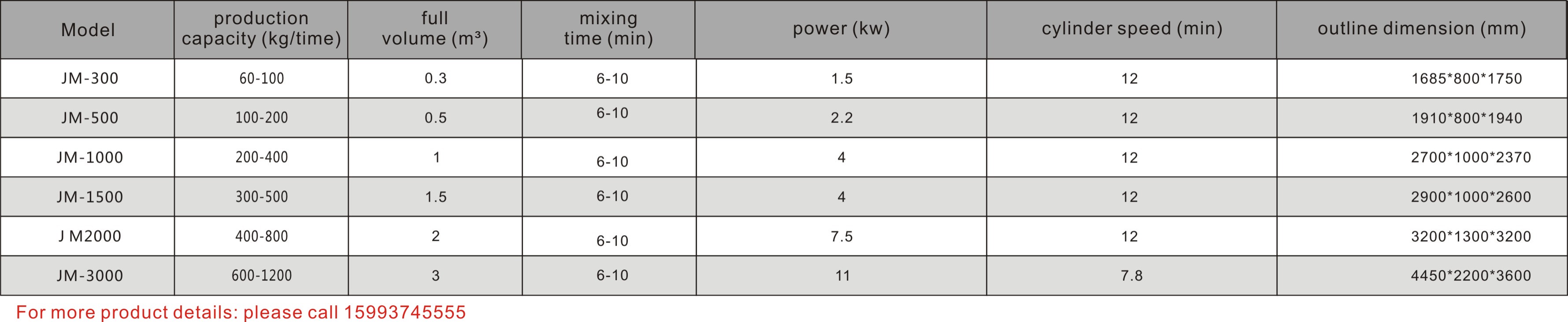

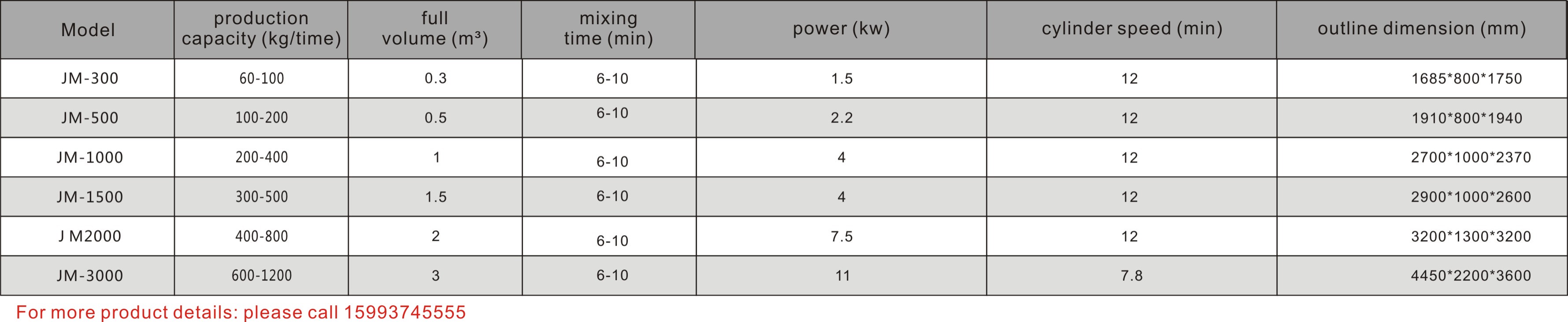

Technical parameters

-

- Commodity name: Waist drum mixer

- Production capacity: 100-300 kg/p

- Applicable materials: Tea, grain, starch, vegetable fiber, milk powder, cocoa powder, flour, coffee, glucose

- Applications: Food, medicine, pesticides, zinc oxide, detergents, veterinary drugs, compound fertilizers, feed, petroleum, mining, building materials industry, coatings, dyes, pigments, auxiliaries, calcium carbonate, biological agents, ceramics, chemicals, flavors and

The screw feeding crushing and mixing machine is mainly suitable for small feed factories and farms. It is suitable for crushing granular materials such as corn and soybean meal. Then mix. The machine adopts the technology of mixing while pulverizing. The pulverizer adopts a screw conveyor to transport the raw materials to be pulverized to the pulverizer. The rotor of the pulverizer can generate positive pressure in the cavity. Very efficient. The pulverized material enters the bottom of the mixing cylinder through the small dial at the bottom of the mixer, and then passes through the mixing shaft for mixing.

Mix together.

-

1. The machine adopts the dust isolation treatment of mechanical seal, which has a reliable sealing effect, the powder will not leak, and will not be damaged due to the rapid wear of the bearing due to the material entering the bearing;

2. The equipment adopts a quick-opening rotary valve, and the discharge port adopts a large-diameter 90° rotary valve, which is easy to use;

3. It can also be used for the mixing of liquid materials;

4. Customized spray or additive device according to customer requirements;

5. It can also be changed to a vacuum dryer.

-

Waist drum mixer is a new type of fine container rotary and stirring mixing equipment. It is used for uniform mixing of various powdery, granular and agglomerated materials. The machine adopts mechanical seal, the powder does not mix and leak, and the bearing has a long service life. The machine has high mixing efficiency, high work efficiency, low labor intensity and convenient operation. The machine is composed of double cones, mechanical seals, frame, deceleration drive, stirring blades, etc. The powder or granular material is added into the double-cone container. With the continuous rotation of the container, the material undergoes complex impact in the container, and the stirring blade rotates at a high speed to achieve uniform mixing.

-

Tel:

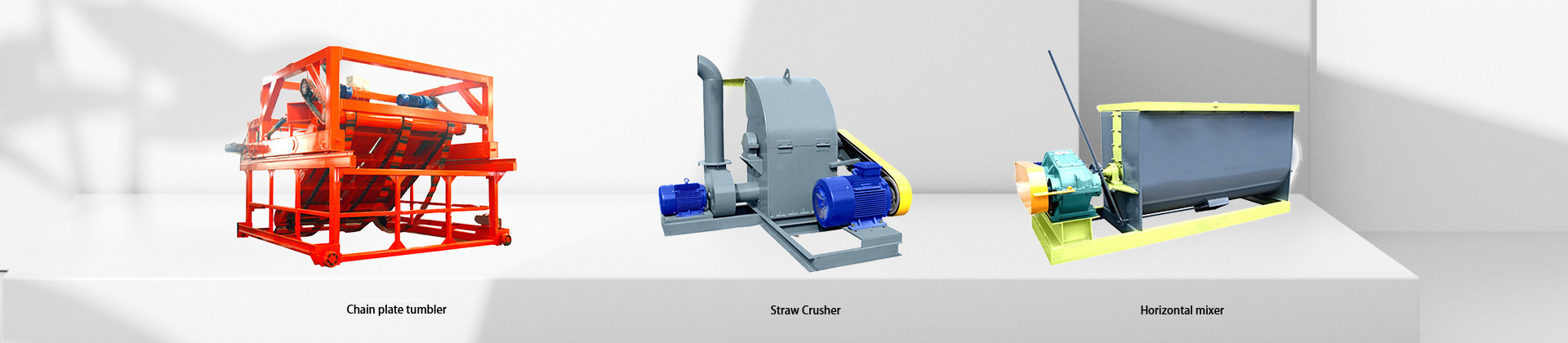

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry