Liquid Adder

- Production capacity: 1-1000t/h

- Applicable materials: Molasses, water,

- Applications: Pasture, etc.

Classification:

Tel:

Introduction

-

(一); Molasses Addition System

Molasses pretreatment equipment: It consists of liquid hot water heating storage tank, high and low liquid level sensor, temperature sensor, stirring device, water pump, control valve, etc.Liquid pretreatment equipment PLC automatic control equipment: composed of programmable controller, touch screen display, weighing control display, etc.

(1) Liquid weighing and spraying integrated equipment: It is composed of liquid weighing tank, high-precision weighing sensor, thermal insulation liquid feeding pump, filter, pneumatic control valve, etc.

(2) Liquid spray equipment: spiral atomized liquid spray head, liquid mixing and distributor components, solenoid valves, high-pressure gas pipes, etc.

(3) Display operation function: On the main screen of the touch screen, the working status, process data and alarm information of the system process can be displayed in real time.(4) Liquid replenishment function: The liquid pretreatment equipment is equipped with a material level detection sensor. When the liquid is at the low limit, the system will automatically alarm with sound and light, and at the same time automatically open the honey pump to replenish the liquid until the liquid reaches the set point.

Set value to stop the honey pump(5) Quantitative honey spraying function: the user can freely set the amount of honey spraying, the liquid weight, and the time interval of honey spraying. The system automatically performs batching and automatic honey spraying according to the user's settings

(6) Record query and report function: Automatically record and store data such as temperature, spray liquid volume, etc., with the function of query.

(7) Delay function: The system equipment has the function of spraying time delay, atomization time delay, cleaning pipeline delay, and adjustable pipeline cleaning time. The system has the function of automatic reset and automatic feeding when the weighing is started.

(8) Cleaning function: use compressed air to automatically purge the liquid spray tank, liquid spray pipeline and nozzle; normally clean the pipeline regularly without blockage.

(9) Protection function: It has the functions of automatic pressurization, decompression, intermittent liquid spraying, system self-protection, etc., so that the electric motors, pumps, valves and other electrical and pipelines are in working condition and prolong the service life of the equipment.

(10) Ease of operation: The operation of the control system is simple and easy to understand, man-machine dialogue, the weight of the liquid to be added can be set on the touch screen, and the batch to be added can be put into production without training.

(two): water addition systemIncluding buffer tank, outlet pump, pipeline, water distributor, automatic valve) The main pipeline sends water to the thermal insulation water tank, with high liquid level control and low liquid level protection, equipped with variable frequency pump to discharge water, and the water adding speed of a single TMR is not less than 60T /min

-

Molasses pretreatment equipment: It consists of liquid hot water heating storage tank, high and low liquid level sensor, temperature sensor, stirring device, water pump, control valve, etc.

-

1. Liquid weighing and pressure spraying integrated equipment: capacity 80kg (water and honey);

2. Single spray time: 25-60 seconds/time (can be adjusted according to the amount of liquid);

3. Liquid spray equipment: 4 spiral nozzles (the amount can be selected according to the amount of liquid);

4. The spraying accuracy is about ±0.5%, and the uniformity is about 90%.

For more product details: please call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: Liquid Adder

- Production capacity: 1-1000t/h

- Applicable materials: Molasses, water,

- Applications: Pasture, etc.

(一); Molasses Addition System

Molasses pretreatment equipment: It consists of liquid hot water heating storage tank, high and low liquid level sensor, temperature sensor, stirring device, water pump, control valve, etc.Liquid pretreatment equipment PLC automatic control equipment: composed of programmable controller, touch screen display, weighing control display, etc.

(1) Liquid weighing and spraying integrated equipment: It is composed of liquid weighing tank, high-precision weighing sensor, thermal insulation liquid feeding pump, filter, pneumatic control valve, etc.

(2) Liquid spray equipment: spiral atomized liquid spray head, liquid mixing and distributor components, solenoid valves, high-pressure gas pipes, etc.

(3) Display operation function: On the main screen of the touch screen, the working status, process data and alarm information of the system process can be displayed in real time.(4) Liquid replenishment function: The liquid pretreatment equipment is equipped with a material level detection sensor. When the liquid is at the low limit, the system will automatically alarm with sound and light, and at the same time automatically open the honey pump to replenish the liquid until the liquid reaches the set point.

Set value to stop the honey pump(5) Quantitative honey spraying function: the user can freely set the amount of honey spraying, the liquid weight, and the time interval of honey spraying. The system automatically performs batching and automatic honey spraying according to the user's settings

(6) Record query and report function: Automatically record and store data such as temperature, spray liquid volume, etc., with the function of query.

(7) Delay function: The system equipment has the function of spraying time delay, atomization time delay, cleaning pipeline delay, and adjustable pipeline cleaning time. The system has the function of automatic reset and automatic feeding when the weighing is started.

(8) Cleaning function: use compressed air to automatically purge the liquid spray tank, liquid spray pipeline and nozzle; normally clean the pipeline regularly without blockage.

(9) Protection function: It has the functions of automatic pressurization, decompression, intermittent liquid spraying, system self-protection, etc., so that the electric motors, pumps, valves and other electrical and pipelines are in working condition and prolong the service life of the equipment.

(10) Ease of operation: The operation of the control system is simple and easy to understand, man-machine dialogue, the weight of the liquid to be added can be set on the touch screen, and the batch to be added can be put into production without training.

(two): water addition systemIncluding buffer tank, outlet pump, pipeline, water distributor, automatic valve) The main pipeline sends water to the thermal insulation water tank, with high liquid level control and low liquid level protection, equipped with variable frequency pump to discharge water, and the water adding speed of a single TMR is not less than 60T /min

-

Molasses pretreatment equipment: It consists of liquid hot water heating storage tank, high and low liquid level sensor, temperature sensor, stirring device, water pump, control valve, etc.

-

1. Liquid weighing and pressure spraying integrated equipment: capacity 80kg (water and honey);

2. Single spray time: 25-60 seconds/time (can be adjusted according to the amount of liquid);

3. Liquid spray equipment: 4 spiral nozzles (the amount can be selected according to the amount of liquid);

4. The spraying accuracy is about ±0.5%, and the uniformity is about 90%.

For more product details: please call 15993745555

Working Principle

-

- Commodity name: Liquid Adder

- Production capacity: 1-1000t/h

- Applicable materials: Molasses, water,

- Applications: Pasture, etc.

(一); Molasses Addition System

Molasses pretreatment equipment: It consists of liquid hot water heating storage tank, high and low liquid level sensor, temperature sensor, stirring device, water pump, control valve, etc.Liquid pretreatment equipment PLC automatic control equipment: composed of programmable controller, touch screen display, weighing control display, etc.

(1) Liquid weighing and spraying integrated equipment: It is composed of liquid weighing tank, high-precision weighing sensor, thermal insulation liquid feeding pump, filter, pneumatic control valve, etc.

(2) Liquid spray equipment: spiral atomized liquid spray head, liquid mixing and distributor components, solenoid valves, high-pressure gas pipes, etc.

(3) Display operation function: On the main screen of the touch screen, the working status, process data and alarm information of the system process can be displayed in real time.(4) Liquid replenishment function: The liquid pretreatment equipment is equipped with a material level detection sensor. When the liquid is at the low limit, the system will automatically alarm with sound and light, and at the same time automatically open the honey pump to replenish the liquid until the liquid reaches the set point.

Set value to stop the honey pump(5) Quantitative honey spraying function: the user can freely set the amount of honey spraying, the liquid weight, and the time interval of honey spraying. The system automatically performs batching and automatic honey spraying according to the user's settings

(6) Record query and report function: Automatically record and store data such as temperature, spray liquid volume, etc., with the function of query.

(7) Delay function: The system equipment has the function of spraying time delay, atomization time delay, cleaning pipeline delay, and adjustable pipeline cleaning time. The system has the function of automatic reset and automatic feeding when the weighing is started.

(8) Cleaning function: use compressed air to automatically purge the liquid spray tank, liquid spray pipeline and nozzle; normally clean the pipeline regularly without blockage.

(9) Protection function: It has the functions of automatic pressurization, decompression, intermittent liquid spraying, system self-protection, etc., so that the electric motors, pumps, valves and other electrical and pipelines are in working condition and prolong the service life of the equipment.

(10) Ease of operation: The operation of the control system is simple and easy to understand, man-machine dialogue, the weight of the liquid to be added can be set on the touch screen, and the batch to be added can be put into production without training.

(two): water addition systemIncluding buffer tank, outlet pump, pipeline, water distributor, automatic valve) The main pipeline sends water to the thermal insulation water tank, with high liquid level control and low liquid level protection, equipped with variable frequency pump to discharge water, and the water adding speed of a single TMR is not less than 60T /min

-

Molasses pretreatment equipment: It consists of liquid hot water heating storage tank, high and low liquid level sensor, temperature sensor, stirring device, water pump, control valve, etc.

-

1. Liquid weighing and pressure spraying integrated equipment: capacity 80kg (water and honey);

2. Single spray time: 25-60 seconds/time (can be adjusted according to the amount of liquid);

3. Liquid spray equipment: 4 spiral nozzles (the amount can be selected according to the amount of liquid);

4. The spraying accuracy is about ±0.5%, and the uniformity is about 90%.

For more product details: please call 15993745555

Technical parameters

-

- Commodity name: Liquid Adder

- Production capacity: 1-1000t/h

- Applicable materials: Molasses, water,

- Applications: Pasture, etc.

(一); Molasses Addition System

Molasses pretreatment equipment: It consists of liquid hot water heating storage tank, high and low liquid level sensor, temperature sensor, stirring device, water pump, control valve, etc.Liquid pretreatment equipment PLC automatic control equipment: composed of programmable controller, touch screen display, weighing control display, etc.

(1) Liquid weighing and spraying integrated equipment: It is composed of liquid weighing tank, high-precision weighing sensor, thermal insulation liquid feeding pump, filter, pneumatic control valve, etc.

(2) Liquid spray equipment: spiral atomized liquid spray head, liquid mixing and distributor components, solenoid valves, high-pressure gas pipes, etc.

(3) Display operation function: On the main screen of the touch screen, the working status, process data and alarm information of the system process can be displayed in real time.(4) Liquid replenishment function: The liquid pretreatment equipment is equipped with a material level detection sensor. When the liquid is at the low limit, the system will automatically alarm with sound and light, and at the same time automatically open the honey pump to replenish the liquid until the liquid reaches the set point.

Set value to stop the honey pump(5) Quantitative honey spraying function: the user can freely set the amount of honey spraying, the liquid weight, and the time interval of honey spraying. The system automatically performs batching and automatic honey spraying according to the user's settings

(6) Record query and report function: Automatically record and store data such as temperature, spray liquid volume, etc., with the function of query.

(7) Delay function: The system equipment has the function of spraying time delay, atomization time delay, cleaning pipeline delay, and adjustable pipeline cleaning time. The system has the function of automatic reset and automatic feeding when the weighing is started.

(8) Cleaning function: use compressed air to automatically purge the liquid spray tank, liquid spray pipeline and nozzle; normally clean the pipeline regularly without blockage.

(9) Protection function: It has the functions of automatic pressurization, decompression, intermittent liquid spraying, system self-protection, etc., so that the electric motors, pumps, valves and other electrical and pipelines are in working condition and prolong the service life of the equipment.

(10) Ease of operation: The operation of the control system is simple and easy to understand, man-machine dialogue, the weight of the liquid to be added can be set on the touch screen, and the batch to be added can be put into production without training.

(two): water addition systemIncluding buffer tank, outlet pump, pipeline, water distributor, automatic valve) The main pipeline sends water to the thermal insulation water tank, with high liquid level control and low liquid level protection, equipped with variable frequency pump to discharge water, and the water adding speed of a single TMR is not less than 60T /min

-

Molasses pretreatment equipment: It consists of liquid hot water heating storage tank, high and low liquid level sensor, temperature sensor, stirring device, water pump, control valve, etc.

-

1. Liquid weighing and pressure spraying integrated equipment: capacity 80kg (water and honey);

2. Single spray time: 25-60 seconds/time (can be adjusted according to the amount of liquid);

3. Liquid spray equipment: 4 spiral nozzles (the amount can be selected according to the amount of liquid);

4. The spraying accuracy is about ±0.5%, and the uniformity is about 90%.

For more product details: please call 15993745555

Tel:

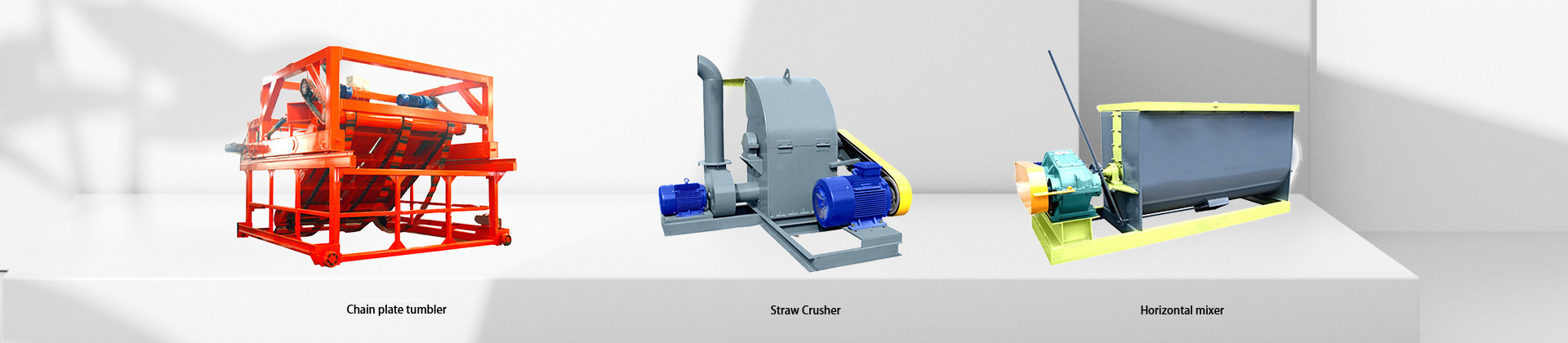

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry